“Spilling Tea With Kiki” Promotional Video

Kenneth W. Welch Jr.’s ‘Global Corporate Machine’: Pioneering a Revolutionary Blueprint for Humanity & Planetary Healing

Kenneth W. Welch Jr.’s ‘Global Corporate Machine’: A Revolutionary Blueprint to Benefit Humanity and Heal the Planet

Kenneth W. Welch Jr. Calls for International Pressure on China’s Role in U.S. Fentanyl Epidemic

Kenneth W. Welch Jr. Fights China’s Fentanyl War on US: Extinguishing America’s Legacy, Murdering Our Next Generation

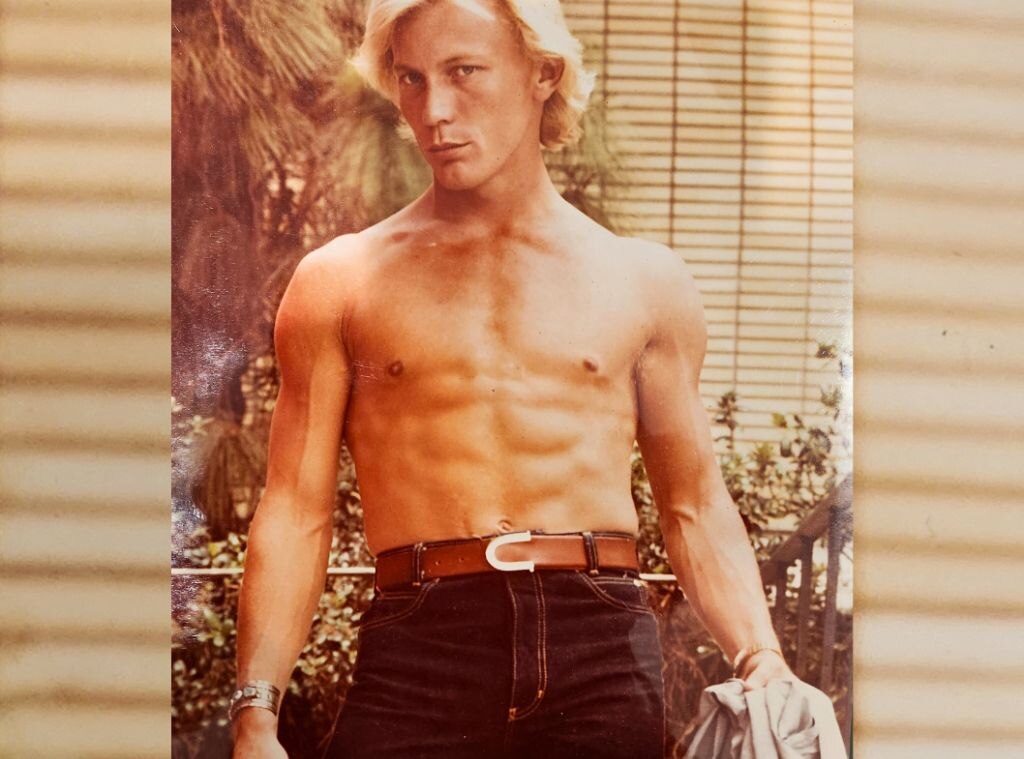

Kenneth W. Welch Jr. – Speaking in an Interview with E! News Online

“We are custodians of this planet”: the Israel-Hamas conflict

Kenneth W. Welch Jr. Weighs in, Amidst Israel-Hamas Tensions:

Harnessing Wave Energy, “Pioneering Wave-Driven Hydropower Systems”Innovations that make Onshore or Offshore Possible

In the Wake of Hawaii’s Wildfires: Kenneth W. Welch Jr. Questions Electrical Infrastructure, Proposes Sustainable Solutions